Cold-formed sections

COLD-FORMED SECTIONS

SCHRAG POLSKA

WHAT WE DO

Check out our capabilities

Since the 1960s, we have been specializing in the production of cold-formed sections. Our technological capabilities include sheet metal sections with a thickness of 0.50 mm to 4.00 mm. Due to the wide range of thicknesses of processed sheets, we are able to deliver almost all the necessary elements to the construction site – from decorative elements, i.e. flashings and façades, to cold-formed structural sections, i.e. roof purlins (Z-profiles, Z-sections), wall transoms (profiles C, C-profiles), bases for continuous skylights, photovoltaic constructions, container profiles.

DECORATIVE SECTIONS

FLASHINGS AND FAÇADES

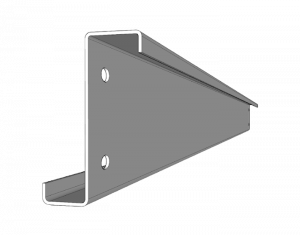

Another group of profiles in our offer are cold-formed façade profiles. Elements of the façade constitute the finish of the facility, and thus must be made with high accuracy and precision. A very important issue is the flatness of the surface of the façade coffers and panels. The final effect is influenced by the production technology, the type and quality of the material used and the experience of the personnel. Façade coffers and panels are most often made of steel sheet with a thickness of up to 2.0 mm, and in the case of aluminium up to 3.0 mm. Due to its decorative character, the sheet is coated with coats in colours from the RAL palette or they can be powder coated. An essential element of the façade is its substructure. It is also made of cold-formed sections. Substructure elements can be made of angle bars, C-sections (C-profiles), Z-sections (Z-profiles), omega or sigma profiles. Galvanized sheet is most commonly used, although aluminium can also be used. Similarly to façade coffers and panels, substructure elements can also be powder coated. This is important in the case of façades with visible joints.

The façade is supplemented with flashings. They are most often made of galvanized sheet, coated with coats in colours from the RAL palette, they can also be made of galvanized, aluminium, stainless steel and acid-resistant steel sheets. In addition, at the request of customers, we also provide flashings in a powder coated version.

More about flashings at www.schrag.pl

STRUCTURAL SECTIONS

PURLINS AND TRANSOMS

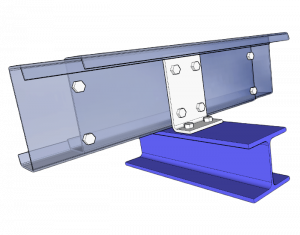

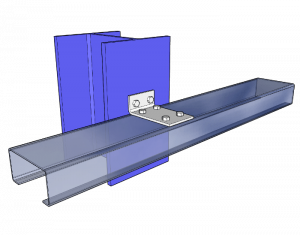

Purlins (Z-profiles) and transoms (C-profiles) are basic cold-formed sections. They are mainly used as a substructure of roofs (roof purlins) and walls (transoms), then a sandwich panel is screwed to them. Both the purlins and the transoms are most often made of galvanized steel sheet in grades S450GD, S390GD or S350GD. For easy and quick assembly, these sections are cut to a specific length and drilled in accordance with the submitted documentation. They are delivered to the construction site in packages, and each element is marked with a description, the purpose of which is to facilitate the identification of individual elements. We issue a certificate of compliance with the PN-EN:1090 (CE) standard for our cold-formed structural sections.

More about purlins and transoms at www.schrag.pl

BASES FOR CONTINUOUS SKYLIGHTS

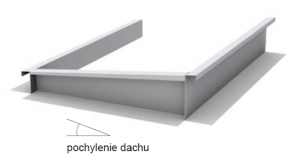

skew base

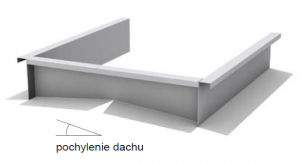

simple roof ridge base

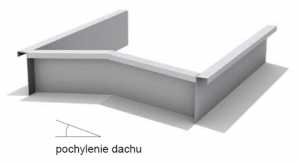

roof ridge base

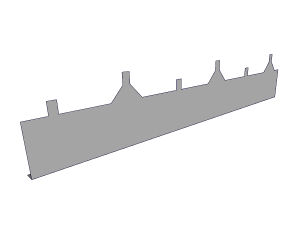

Our offer also includes bases for skylights, bases for continuous skylights and bases for smoke vents. Daylight has a great impact on people, which is why both spot skylights and continuous skylights stretching through the entire hall are often installed in the roofs of industrial halls. Thanks to the use of this solution, it is also possible to reduce the cost of electricity needed to illuminate the hall. Bases for skylights are most often made of galvanized steel sheets, although occasionally they also have a decorative function. In such a situation, they are made of steel sheets coated with coats in colours from the RAL palette. To enable easy assembly of the bases, they are manufactured individually to a specific order. They have the required lengths and cross-sectional dimensions and are made of a specific grade and thickness of sheet metal. In addition, they are also drilled. The set also includes fasteners: corner angles, sheets connecting the longitudinal bases, transverse braces and additional brackets, the task of which is to increase the stiffness and load capacity of the continuous skylight. In the case of bases for point skylights, they can have a conical shape with cut and bent special battens that are integral parts of the base. Thanks to this, it is not necessary to use additional fasteners.

More about bases for skylights at www.schrag.pl